Making the Case: Why Steel is Real

When it comes to the Black Bay, 316L steel is manipulated into a finely crafted case.

When it comes to case materials in watchmaking, there’s a reason Stainless Steel is ubiquitous. It’s resistant to corrosion, it’s durable with a high level of resistance to impacts, and it can hold a number of finishes over time. Additionally, it’s an alloy that offers a lot of value. TUDOR’s core product development philosophy is providing the best watch at the best price, and oftentimes that leads to the utilization of stainless steel.

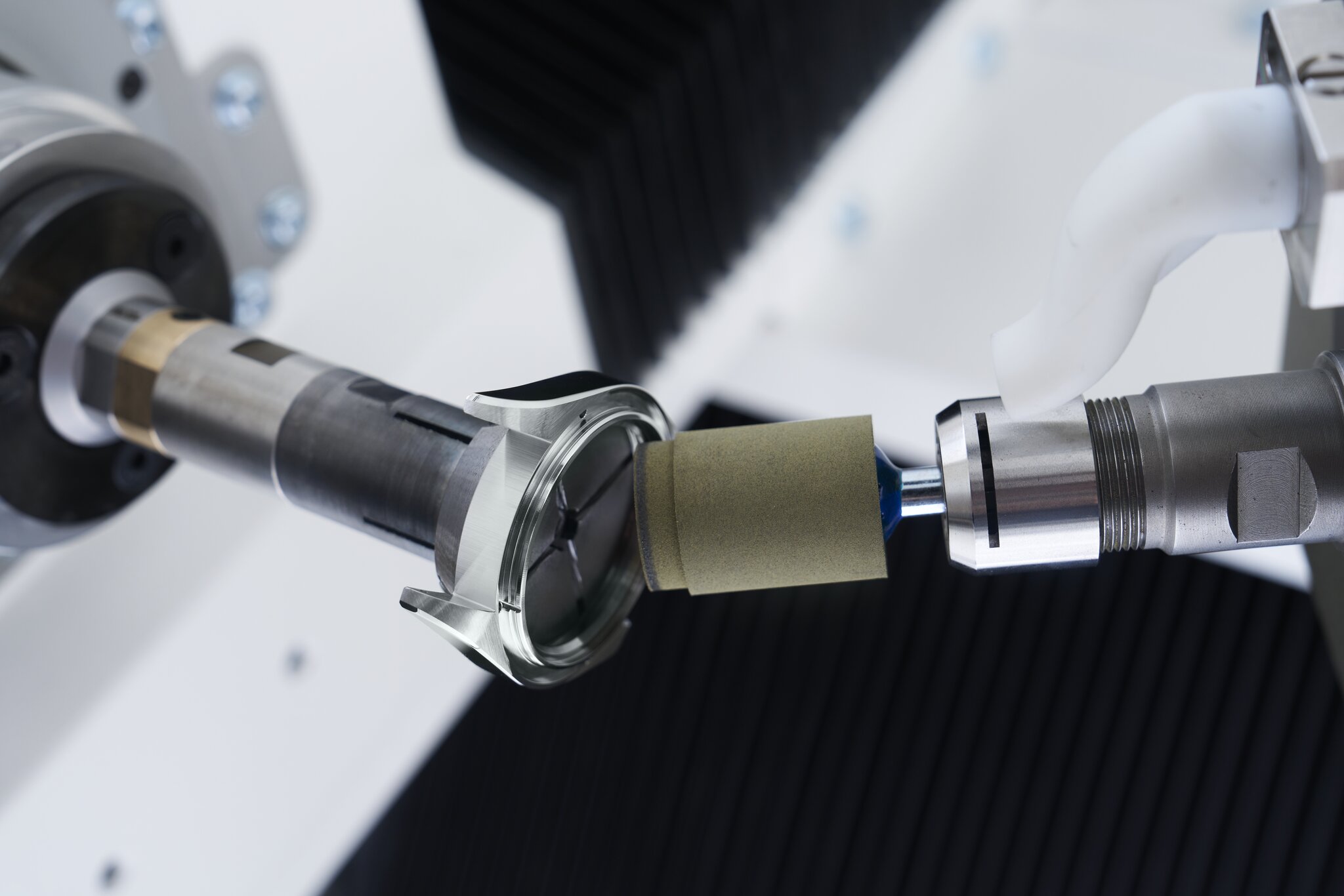

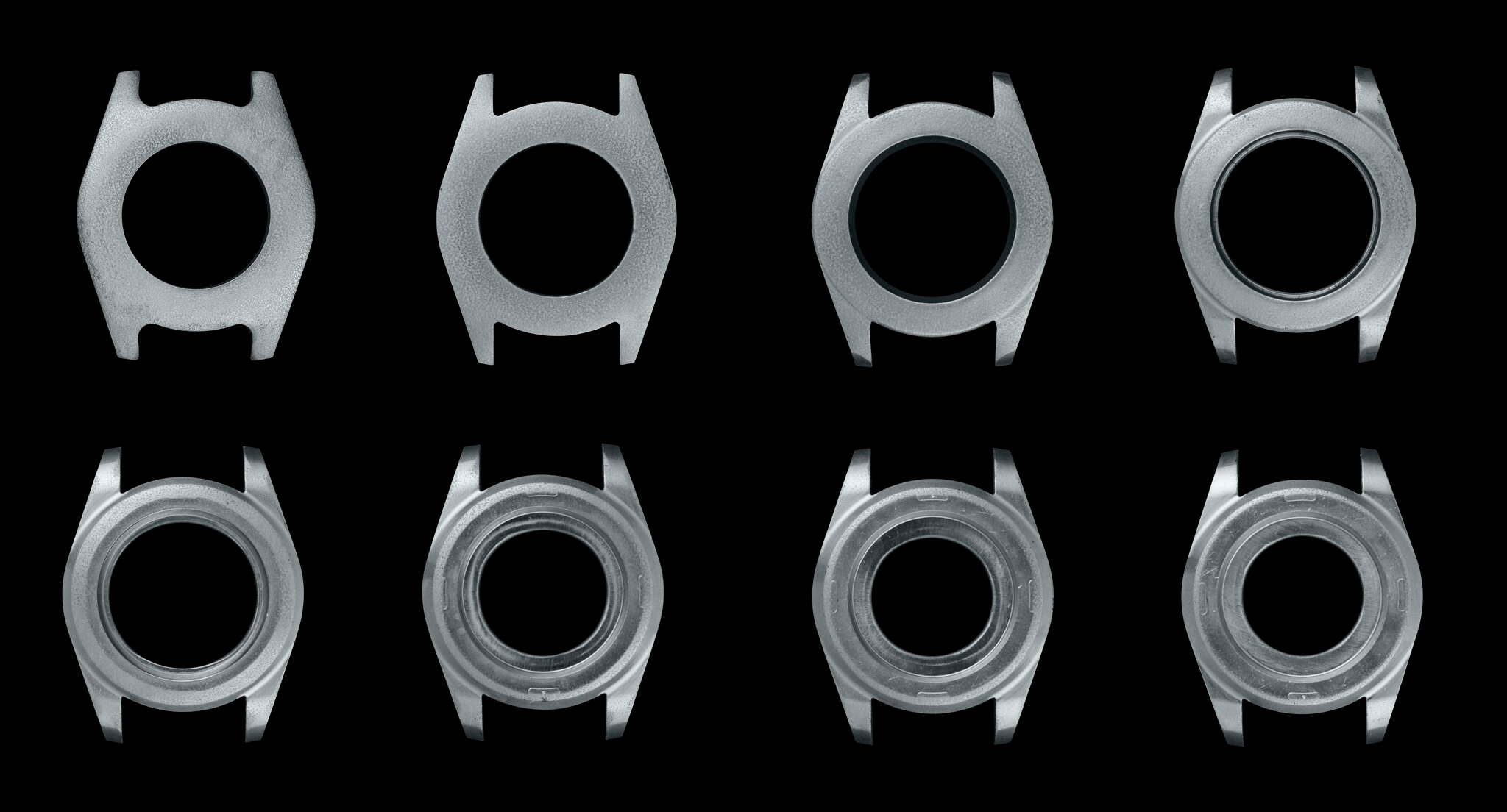

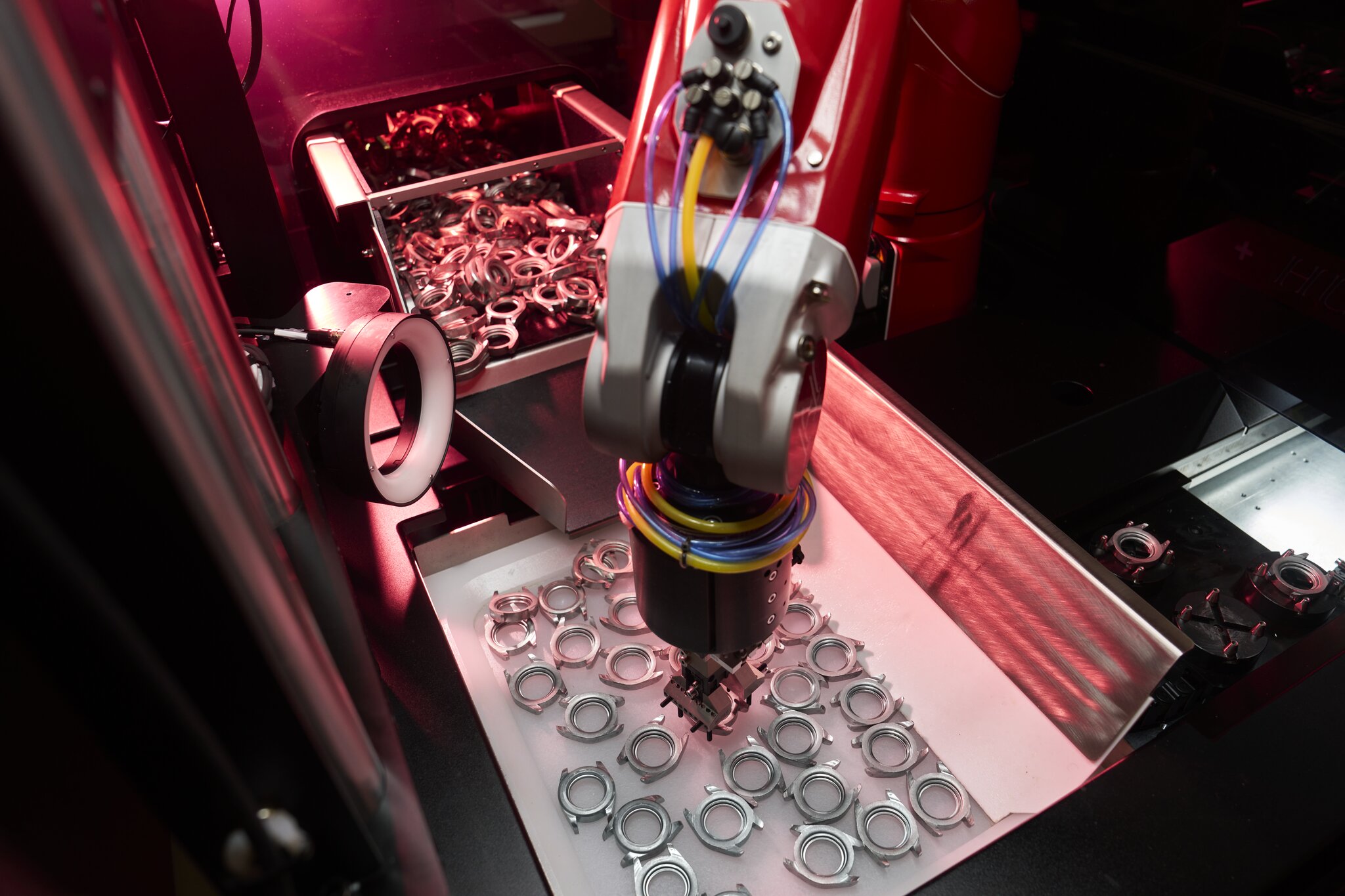

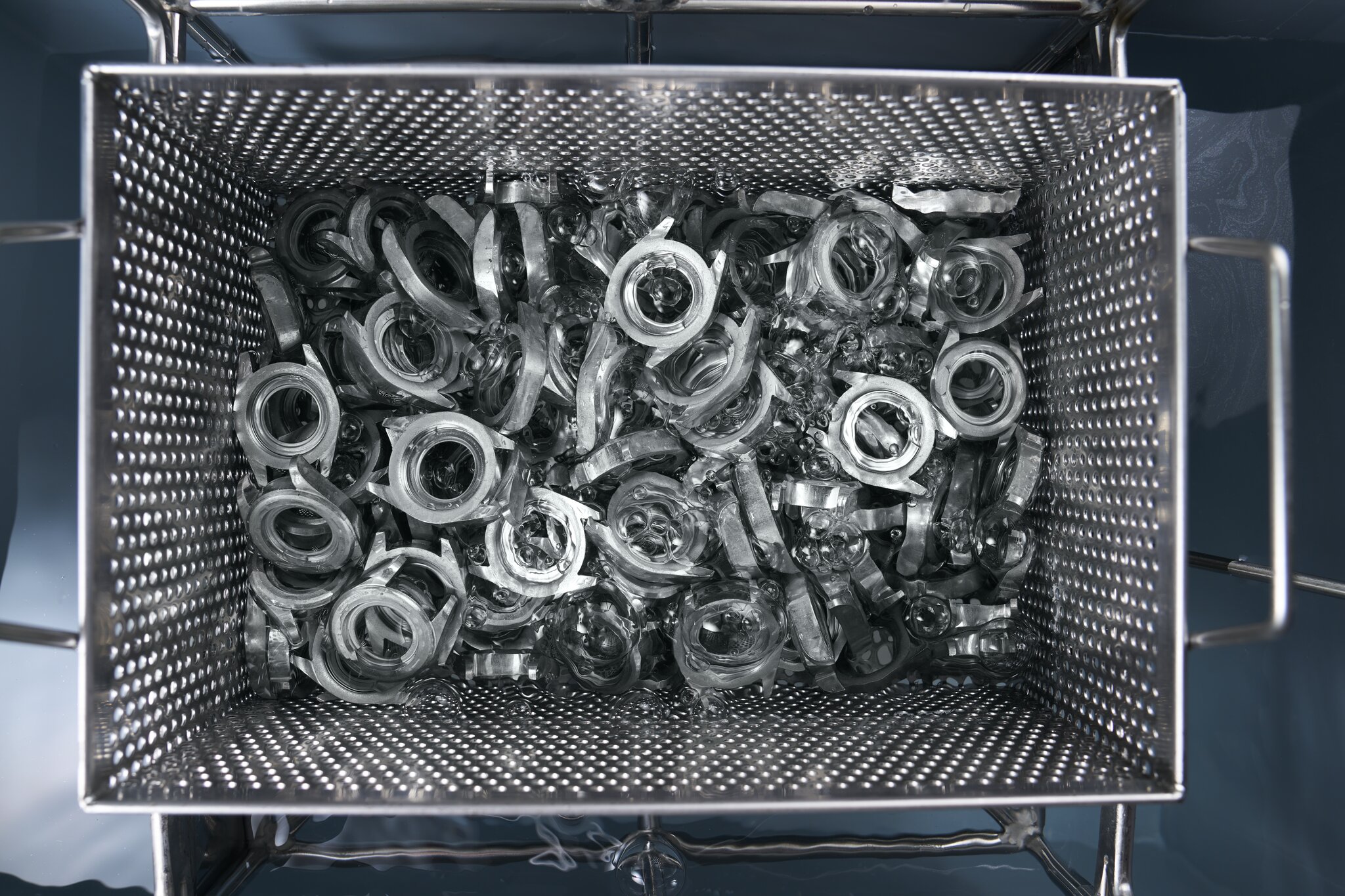

Every Black Bay starts with a solid “blank” of 316L stainless steel. Each blank is just slightly thicker than a case. TUDOR’s case making is done through “subtractive manufacturing” wherein a blank is milled and machined down, so starting with a blank roughly the size of a case means less material is wasted. The inside of the case is punched out first, then the whole case follows. This early-stage case is then machined further into the distinctive shape of the Black Bay case. The cases are heat-treated and strengthened before being polished, by hand, in a variety of finishes to add visual interest to the design.

Working with stainless steel is complex, but in the end, it’s what lends a unique character to the Black Bay.

Watches mentioned

Related articles

View all news

TUDOR Celebrates the Miami GP With a Unique Black Bay

For the Miami GP only, VCARB drivers wear a very special Tudor matching their cars' exclusive livery

#news

Tudor Pro Cycling Team Takes on the Giro d'Italia!

This is the first ever Grand Tour for the team, only two years after its creation.

#news

Visit the TUDOR Boutiques in Geneva and Zurich Next Week!

Want to see all the new TUDOR watches from Watches and Wonders? The boutiques in Geneva and Zurich will have them—and you can even leave with a new watch, too.

#news

TUDOR GOES PINK, AGAIN! THIS TIME WITH A BRAND-NEW WATCH!

The Black Bay Chrono “Pink” might not be for everyone, and that’s OK because few of them will ever be made.

#news